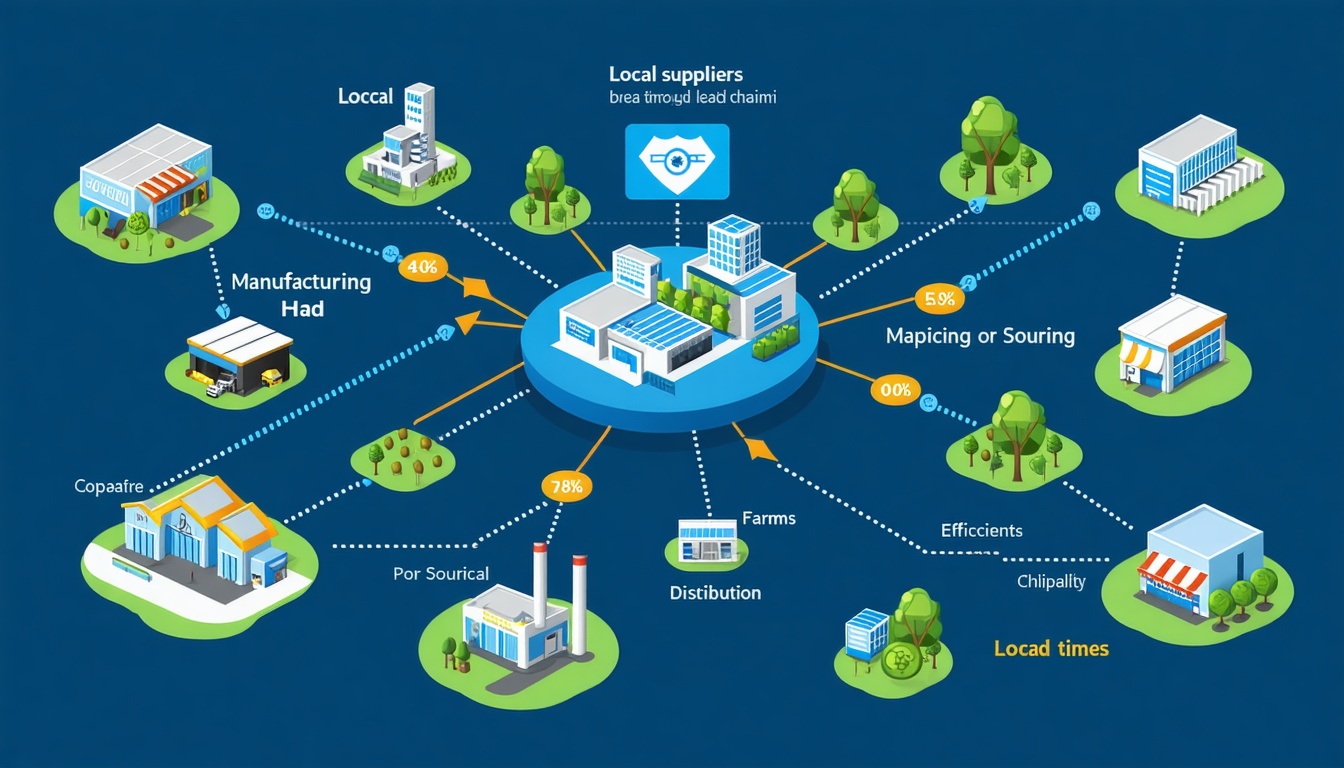

Local Sourcing Benefits

Local sourcing is like having the ultimate cheat code for furniture companies. Cut down on waiting around for products to arrive, and you’ve got yourself a winning strategy for making your supply chain slicker and shortening the time it takes to get that new armchair into your living room. Sticking with fellow locals makes everything from decision-making to distribution way easier to handle.

Enhancing Supply Chain Efficiency

Teaming up with local suppliers means saying goodbye to those frustrating shipping wait times that pop up when you order stuff from halfway across the globe. It’s a straight-up tourniquet for those headaches involving customs checks, tariff battles, and snail-paced ocean freighters. You know exactly who you’ve got on your team and when you need your next batch of goods to hit the tarmac.

Keeping your shelves full is also key. If the cupboard runs bare, you’ll have customers tapping their feet. With your local allies, inventory juggling becomes a breeze. And by tweaking your stockpile strategy right, you’ve got the goods when you need ‘em.

Let’s talk about moving stuff around, too. The shorter the trip, the faster the whip. Keeping your suppliers close means you can slam down those nuisance transport wait times. Fine-tuning those delivery plans will keep everything rolling smoothly, and it’s bound to put a smile on your customer’s face when their much-anticipated delivery shows up like clockwork.

| Factor | Benefit |

|---|---|

| Local Sourcing | Slices through shipping slogs and red tape |

| Inventory Management | Guarantees products are ready and waiting |

| Transportation Efficiency | Cuts down waiting times and streamlines routes |

Reducing Lead Times

When it comes to speed, local is the way to go. Shortening the hop between supplier and manufacturer means less foot-dragging in getting raw materials where they need to be. By cozying up to suppliers in your backyard, you’re in for faster back-and-forths, which is golden for teamwork.

Switching gears swiftly to meet the latest eco-craze or running corrections on the fly isn’t just possible, it’s practical. For a furniture business, riding the wave of green-friendly goodies or adopting a circle-back approach to production is made easier with local sourcing. Tapping into quick-change strategies for furniture manufacturing keeps your operation humming, ensures orders aren’t left hanging, and checks all the right boxes for being environmentally accountable.

If you’re looking to keep pace with demand and beef up that supply chain, going local is the secret sauce. For extra tips to amp up your furniture-moving game, visit our expert page on amping up your furniture supply chain moves.

Challenges in Global Supply Chains

While scouring the globe for materials and suppliers gives companies more options, it can also stir up a storm of issues that mess with delivery times and mess up efficiency. Getting a grip on these hiccups is key for firms aiming to boost their supply chain mojo by snagging quicker deals through nearby suppliers.

Hidden Costs of Global Sourcing

Going global with your sourcing can be tempting with its upfront savings, but don’t be fooled. There are sneaky costs lurking behind those initial price tags, and they can quietly chip away at those savings. Here’s the lowdown:

| Cost Factor | Description |

|---|---|

| Transportation Costs | Shipping stuff long distances gets pricey, fast. Think fuel, logistics, and the like. |

| Customs and Tariffs | Import taxes sneak up on you, adding costs you didn’t see coming at first. |

| Inventory Holding Costs | Waiting longer on deliveries might make you stockpile more than you’d like, bumping up storage costs. |

| Quality Control Issues | Juggling multiple suppliers means quality can slip through the cracks – hello, recalls and losses. |

| Delays and Disruptions | Political messes, Mother Nature’s tantrums, or shipping slowdowns can bring surprise expenses. |

Smart furniture supply chain optimization strategies need to anticipate these stealth costs, especially if you’re chasing eco-friendly goods or jumping on the circular production bandwagon.

Risks of Lengthened Supply Chains

Stretching out that supply chain might look like a power move, but it ramps up the risks that can throw a wrench in your operation. Here are some biggies to watch out for:

-

Supply Chain Disruptions: From pandemics to trade wars, global chains are like sitting ducks for disruption. Your materials could be waylaid, impacting production.

-

Quality Assurance Challenges: Keeping tabs on quality across different countries is tricky business. Different standards across borders might lead to wonky products.

-

Increased Complexity: More links in the chain mean more room for error. Communication and coordination can go right out the window, messing up those lead times.

-

Regulatory Compliance: Different rules in each region are a headache. Companies have to juggle compliance with labor and environmental laws, making sourcing globally a tightrope walk.

To dodge these bullet points, more companies are eyeing local suppliers to trim down their supply chains, adding a layer of resilience. As they face these hurdles, checking out furniture manufacturing lead time reduction and strategies can give them the wiggle room needed to meet the growing demand for green products without breaking stride.

Strategies for Lead Time Optimization

Furniture companies have a tough gig. Everyone’s looking for that perfect coffee table, and they’re not willing to wait forever. Hence, nailing lead times is super important, especially when folks are leaning towards eco-friendly choices and quicker turnaround. Going local is a good hack to up your game in both speed and going green.

Partnering with Domestic Suppliers

Want to make things snappier? Stick to nearby suppliers. Partnering with suppliers close by helps dodge those shipping hiccups that international suppliers might throw your way. Keeping things local means quicker trips for goods, making delivery schedules feel as reliable as your morning coffee.

| Why Going Local Rocks | What it Does for You |

|---|---|

| Quick Delivery | Speeds up the time from ordering to receiving. |

| Dependable Arrivals | Cuts down on shipping hold-ups. |

| Eco-Friendly Boost | Helps the neighborhood grow and trims down on pollution. |

When firms choose their next-door buddies, it’s a win-win. They get to quickly assemble stuff with local materials and manpower, spiking their production speed. Better still, when demand shoots up, they won’t be left in the lurch. Throw in moves like offsite sub-assemblies, and efficiency skyrockets. Want more inside scoop? Check out furniture supply chain optimization strategies.

Importance of Supplier Performance

Supplier performance isn’t just a box to tick—it’s a major player in making lead times work. Companies need suppliers that live up to their promises on material arrivals. Sticking with the good ones keeps customers smiling and sustains brand reputation.

Keeping an eye on things like prompt delivery and material quality helps firms zero in on top-notch suppliers. Tools such as Veridion make finding new supplier buddies a breeze, especially when demand ebbs and flows.

| Supplier Performance Must-Knows | What to Observe |

|---|---|

| Delivery Punctuality | How often orders show up on time. |

| Material Quality | How good the received materials are. |

| Quick Response | Speedy answers to questions and problems. |

Having a handle on managing lead times, along with giving supplier performance a good old review, keeps furniture companies from losing their edge. Dive deeper into shaping up industry lead times in this article on furniture industry lead time optimization and see more tricks on shrinking lead times in furniture logistics.

Procurement Lead Time Management

Getting a grip on lead times in procurement is key if companies want to keep operations smooth and stay on top of what customers expect. Let’s check out the elements that can shuffle the timeline in procurement and some handy tools to forecast those timelines effectively.

Factors Affecting Procurement Lead Time

Lead time in the world of procurement is basically the countdown from the moment you hit ‘send’ on an order to when those goodies land on your doorstep. A bunch of things can throw that timeline off:

| Factor | How It Messes with Time |

|---|---|

| Supplier Trustworthiness | Sketchy suppliers bring delivery hiccups and surprise product shortages. |

| Transportation Choices | Whether you fly it, sail it, or truck it, that choice messes with the delivery speed. |

| Order Size | Giant orders might clog the system, but too many tiny ones can make time crawl. |

| Customs Nonsense | If you’re ordering from afar, customs can add a wildcard to the wait time. |

Teaming up with reliable suppliers nearby can chop down the time it takes for shipments to land. Working with local folks means fewer long-haul complications and customs headaches. Dig into our piece on furniture supply chain optimization strategies for more juicy details on local sourcing perks.

Tools for Efficient Lead Time Forecasting

A couple of go-to tools can help keep those procurement lead times from running wild. Tech like Veridion puts a spotlight on how suppliers perform and how reliable they actually are, making sourcing quicker. Here are some more gadgets and gizmos:

- Transport Management Systems (TMS): Track your stuff in the here-and-now, leading to better coordination and faster fixes when stuff goes sideways.

- Economic Order Quantity (EOQ): This math trick helps nail down the sweet spot for order size to keep costs in check and efficiency humming.

- Inventory Management Software: Keeping tabs on stock levels can fend off those dreaded out-of-stock signs, which directly affects how quickly you can get products to your customers.

By rolling out these tools and getting a handle on what’s messing with lead times, companies can level up their procurement game and shave off unnecessary delays. For a deep dive into lead time tricks just for the furniture game, check out our article on furniture manufacturing lead time reduction. Plus, our insights on reducing lead times in furniture logistics are packed with tips to get your logistics game on point.